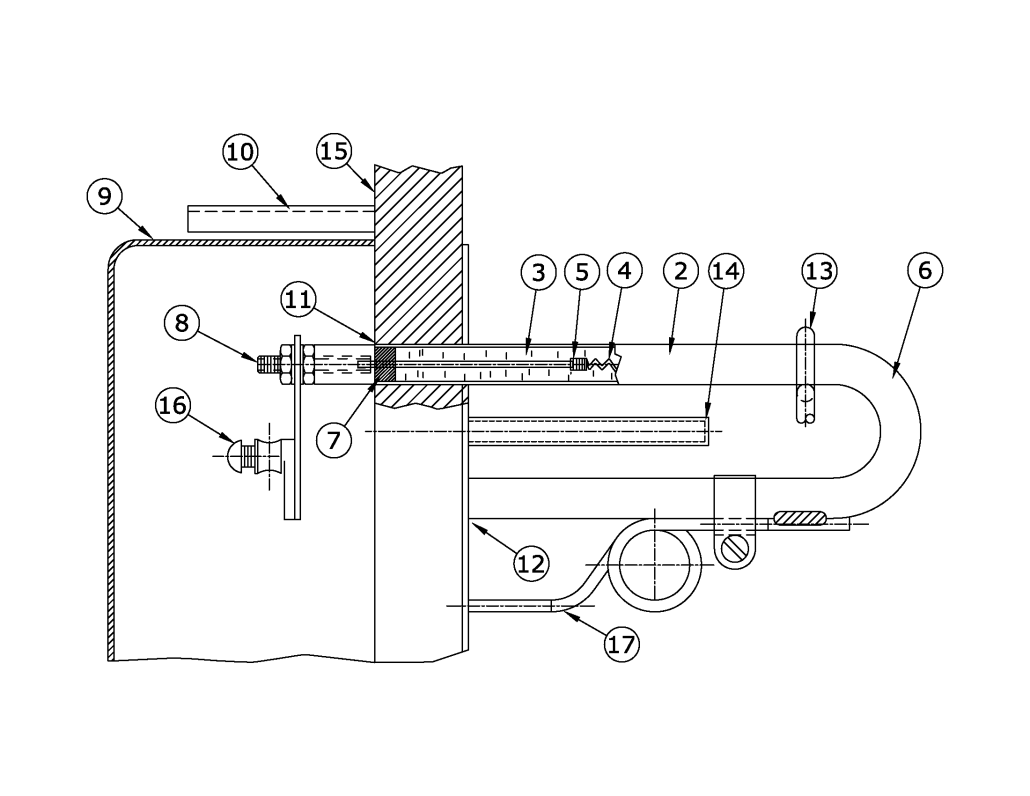

Flange immersion heaters are designed for use in tanks and pressurized vessels to heat both gases and liquids. A flanged immersion heater will typically mate with a companion flange that is either welded to a tank or in the case of circulation heaters, to a pipe body. AccuTherm flange heaters are designed to provide our customers with a long-lived, dependable, trouble-free heater for their application requirements. A properly designed flange heater will provide a high degree of efficiency as the energy that is generated is quickly dissipated directly into the medium that is being heated.

1. UL & CSA Recognition on Elements.

2. Incoloy 840® sheath standard on all items-allows for the widest coverage of applications and temperatures, plus gives a margin of safety should there be any unknown corrosives or contaminants in the solution.

3. High purity MgO powder compacted to provide maximum heat conductivity and optimum dielectric strength.

4. Type ‘A’ 80/20 resistance wire sized to provide the lowest wire watt density for maximum life.

5. Fusion welded junction between pin/resistance wire to provide a 360° circumferential joint, giving superior strength and life.

6. Re-compacted bends to restore MgO density in bend areas.

7. Moisture sealed to prevent the entrance of contaminants during storage and service. Silicone end seals on heaters for oil, air, and corrosive applications. Epoxy seals for water applications.

8. #10-32 terminals for wiring connections.

9. Standard Nema 1 housings on all catalog items. Seamless deep-drawn housings provide easy accessibility to wiring.

10. Fixed conduit support bracket. The supply conduit is not disturbed when the cover is removed.

11. Welded construction between elements and flanges on steel and stainless steel headers to give maximum corrosion protection and strength at elevated temperatures. All welds are hydrostatically pressure tested for leaks.

12. Silver braze construction on nonferrous flanges.

13. Spacer supports on units where immersed length exceeds 18″. This feature prevents adjacent elements from touching and overheating plus allows for easier assembly and disassembly from the mating flange.

14. ½ ” O.D. thermowells for existing or optional thermostats.

15. Standard flanges 150 Ib. rating ASA drill pattern ‘A6 raised face, other weights available.

16. Screw type lug line connectors for positive secure field connection points.

17. Optional MgO filled thermocouples attached to the sheath. This feature provides positive sensing protection for overheat situations. Thermocouple junction location should be at the area of highest operating temperature. (High Limit push to reset controllers available for thermocouple signal.)

18. 100% inspected for:

A. Dielectric or Hi-Pot between conductors and sheath.

B. Insulation resistance.

C. Wattage.

D. Hydrostatic pressure test which also insures the sheath is defect-free.

ADDITIONAL OPTIONAL FEATURES

- Nema 4 or 7 moisture or explosion resistant enclosures available on all flange sizes.

- Standoff housing design for high temperature applications.

- Thermostatic controls in Nema 1, 4 or 7 enclosures available in (3) temperature ranges.

- Thermocouples in either type J or K for control or high limit protection.

- Other sheath materials … Incoloy 800, 304, 316 stainless, Carpenter 20, Monel 400, lnconel 600, Hastelloy and Titanium.

- Type 304 or 316 stainless steel flanges.

- Passivated elements and flanges for pure and deionized water, photo chemicals and special processes.

- Special lengths, wattages and voltages … consult factory.