Cast Materials

Cooling Methods

None

This cast-in does not need a cooling feature.

Liquid Cooled Band – Single Set of Cooling Tubes

The single set cooling tube design features 1/4″, 3/8″ or 1/2″ diameter tubing precisely formed into a serpentine or any other suitable shape and cast into the body of the Cast-In Heater. This is the most widely used method for providing a means of cooling in liquid-cooled Cast-In Heaters. From this basic design, the user can choose to factory equip the cooling tubes with any of the cooling tube termination options.

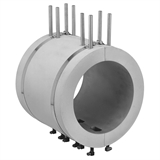

Liquid Cooled Band – Dual Set of Cooling Tubes

The Dual cooling tube design incorporates two sets of 3/8″ or 1/2″ diameter tubing formed into a serpentine or any other suitable shape within the same Cast-In Heater. Dual cooling tubes will actually double the operating life of a Cast-In Heater with liquid-cool function since cooling tube failures usually occur before heating element failures

Liquid Cooled Band with Recessed NPT Fittings

The recessed cooling tube design incorporates 3/8″ or 1/2″ diameter tubing formed into a serpentine or any other suitable shape with specially designed stainless steel NPT fittings that are welded to the tube ends and cast below the surface of the Cast-In Heater, thus eliminating the troublesome, commonly used tube extensions as they exit the casting for connection to the coolant lines.