Across process applications, maintenance teams are in a constant battle to maintain operational productivity and minimise downtime. Although maintenance team resources are often stretched, implementing data-driven diagnostics can enhance their capabilities. This approach can minimise the potential of maintenance challenges developing long-term, as well as increasing the speed of response to emergency situations. The good news is that the required hardware might already be installed as an existing feature of process control. Even if not, integrating the right technology could be easy to set-up, and provide a fast return on investment.

Today, there’s an availability of data throughout industrial processes like never before. Whether it’s the water treatment sector, food & beverage production, or pharmaceutical manufacture, data is everywhere. The significant advantage for maintenance engineering teams is the improvement to diagnostics it can help to achieve. Data analysis can give an awareness that enhances preventative maintenance, minimising the prospect of unexpected downtime. In the event of maintenance emergencies, data can also enable a faster, more effective response.

The crucial advantage of automated control is that data, whether emerging from a component such as a valve or a sensor, can be collected, in real-time, in a continuous stream. As a result, this data can be analysed to provide reports, giving intelligence over time to enable effective diagnostics, as well as automated alerts.

However, this data omnipresence can be overwhelming. For a data-driven approach to help achieve effective diagnostics, maintenance teams need a clear plan of what data they need, and how they’re going to collate and analyse it. While establishing this initial process management stage takes time initially, embracing data availability can reduce the time, cost, and efficiency of maintenance engineering in the long run.

A common challenge is an awareness of what to do with the available data, and the benefits that effectively managing it can bring. A workable approach to identify where to collate data from, is to prioritise the equipment, as well as their constituent components, in an operations-critical order. This inventory will span a time period of urgency, from issues that would demand emergency attention, to challenges that could signal a longer-term problem. Crucially, this approach will also identify the condition indicators from which data needs to be collated and managed to achieve effective diagnostics.

As a result, the maintenance engineer can instantly realise if the fault lies with the sensor, or make a fast progression with the diagnostic procedure. Additional digital alarms may have triggered in parallel, but even if not, sensors from upstream devices, such as dosing pumps or control valves, can be compared to diagnose the issue, all from a remote setting.

Effective preventative maintenance

For urgent maintenance requirements, a data-driven system can also provide an operational comparison over time, giving greater context to help understand the actual source of the fault, supporting a faster response. However, historical data analysis is the basis of the real advantage for diagnostics; identifying trends over time gives the capability to make effective preventative maintenance.

By continuously monitoring data over a long-term period, maintenance teams can detect drift or inconsistencies to identify, and resolve, issues that could develop into significant challenges if left unchecked. This could range from corrosion caused by elevated pH levels over a long period, through to malfunction resulting from extended exposure to excess heat.

As well as monitoring parameter levels that could cause maintenance problems, data analysis can also directly inform on component or system health. Setting up an alert according to the number of cycles completed by a pilot valve, for example, can action a maintenance check, and any remedial action required, before an unexpected breakdown due to end of life can occur.

Implementing data diagnostics

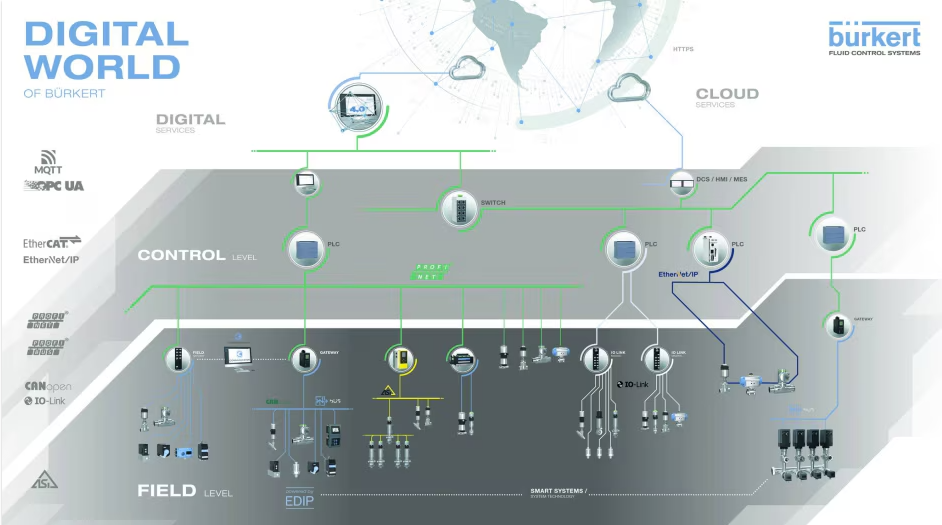

If the process system already involves sensors for purposes of production quality and safety, data could be drawn from these sources. However, if new data capture devices are required, a common challenge to implementing data diagnostics for maintenance needs is the requirement for PLC integration and the demand on programming expertise. Today though, a range of sensors and meters are available with integrated PC tools to enable fast commissioning and straightforward operation, without requiring programming expertise. These devices are usually available with Ethernet-based communications, such as Profinet, so they can also integrate with PLC systems when required.

Valves are vital to virtually all process control systems, and to manage a valve array and enhance preventative maintenance, a valve island like the Bürkert Type 8652 can send data to any configured device, ranging from a smartphone to a PLC. This enables remote monitoring with automated, configurable alerts. It can also achieve trend monitoring and historical reports, with data relating to parameters such as switching time function or manifold pressure, through to total number of cycles.

- Safety-related shut-off of valves possible

- Higher plant availability with PROFINET S2 (system redundancy)

- Process reliability through pneumatic functions

- Optimised for installation at the bottom of the control cabinet

- EX-Versions: ATEX / IECEx Zone 2, cURus Haz. Loc. CL I, II, III Div 2

To monitor the parameters of the media involved in the process, a variety of sensors for maintenance diagnostics can also be integrated without the direct requirement for a PLC. For example, to monitor drinking water or fresh water in industrial processes, the Bürkert Type 8906 Online Analysis System enables the modular integration of sensors such as pH, free-chlorine, and turbidity, that can also be monitored remotely via available GSM modules. These sensors can also be combined with volumetric flow meters that can also provide diagnostic data in addition to their typical process control roles.

- Water analysis configured in accordance with customer’s wishes

- Continuous analysis of drinking water and industrial process water

- Based on the modular Bürkert cube and backplane technology

- Fieldbus connection for versatile industrial communication, data exchange via mobile gateway

- Extremely low-maintenance and long service life thanks to MEMS technology

Low cost of ownership

Although the integration of data for diagnostics requires planning, the initial time investment can pay dividends to achieve more efficient maintenance engineering long-term. The data-driven approach means a more proactive response to maintenance, without the need to increase available engineers.

While maintenance teams may be able to draw on the data available from already installed hardware, even if investment is required for equipment such as additional probes or valve islands, the resulting productivity gains from enhanced diagnostics can generate a low total cost of ownership for the long-term.