EtherNet/IP™ is a widely adopted Ethernet communication network that provides users with the tools to deploy standard Ethernet technology (IEEE 802.3 combined with the TCP/IP Suite) in industrial automation applications. The EtherNet/IP and CIP technologies are managed by ODVA, Inc., a global trade and standards development organization.

EtherNet/IP offers various network topology options including star or linear with standard Ethernet infrastructure devices, or device level ring (DLR) with specially enabled EtherNet/IP devices. Compliance with IEEE Ethernet standards provides users with a choice of network interface speeds – e.g., 10, 100 Mbps and 1 Gbps – and a flexible network architecture compatible with commercially available Ethernet installation options including copper, fiber, fiber ring, and wireless.

EtherNet/IP™ implements CIP at the Session layer and above and adapts CIP to the specific EtherNet/IP™ technology at the Transport layer and below. EtherNet/IP uses standard IEEE 802.3 technology at the Physical and Data Link layers. EtherNet/IP can accommodate an unlimited number of point-to-point nodes. At the Network and Transport layers, EtherNet/IP utilizes standard TCP/IP (Transmission Control Protocol/Internet Protocol) to send messages between one or more devices. For real-time data transfer, EtherNet/IP also employs UDP over IP to transport I/O messages that contain time-critical control data

EPC’s EtherNet/IP Encoders:

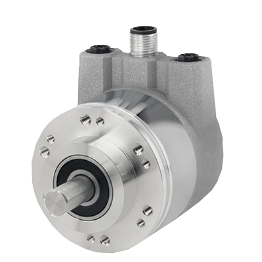

- Single or multi-turn absolute shaft encoder

- Single/multi-turn absolute encoder (16 Bit ST / 43 Bit MT)

- 58 mm (2.28”) diameter package

- Available in three industrial Ethernet protocols:

-

- EtherCAT® with CoE, FoE, EoE – device profile: CiA DS-406 V4.0.2, Class 3

- EtherNet/IP™ position sensor, DLR

- PROFINET® I-O (CC-C) – device profile: switchable V4.1, Class 3, 4

- Maintenance-free and environmentally-friendly magnetic design

- Energy-harvesting magnetic multi-turn technology

- No gears or batteries

- Low TCO and easy provisioning with internal web server

- Shaft loads up to 400 N

- Color LEDs for operating condition, bus status, link activity

- Compact design with bus cover

- MP housing option is most the compact EtherCAT® and PROFINET® model available

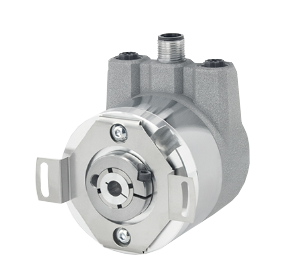

- Single or multi-turn blind hollow bore encoder

- Single/multi-turn absolute encoder (16 Bit ST / 43 Bit MT)

- 58 mm (2.28”) diameter package

- Available in three industrial Ethernet protocols:

-

- EtherCAT® with CoE, FoE, EoE – device profile: CiA DS-406 V4.0.2, Class 3

- EtherNet/IP™ position sensor, DLR

- PROFINET® I-O (CC-C) – device profile: switchable V4.1, Class 3, 4

- Maintenance-free and environmentally-friendly magnetic design

- Energy-harvesting magnetic multi-turn technology

- No gears or batteries

- Low TCO and easy provisioning with internal web server

- Color LEDs for operating condition, bus status, link activity

- Compact design with bus cover