In aluminium die casting, reproducible process conditions are an important basic requirement in order to be able to supply cast parts of a consistently high quality. Foundries must therefore also address the issue of cooling, as efficiently controlled cooling has a decisive influence on part quality. Documenting the actual cooling parameters therefore makes a decisive contribution to process reliability and product quality.

Modern cooling solutions for die casting machines:

Precise cooling plays an important role in low-pressure die casting, as it has a direct impact on the quality of the cast parts. The correct mould cooling therefore influences the entire production in the foundry.

Efficient and safe die casting processes:

Cooling is an indispensable process step in low-pressure casting. If cycle times in aluminium die casting are to be reduced to enable more efficient production, a particular focus must be placed on well-coordinated cooling. To permanently achieve a desired product quality, the correct mould cooling is decisive.

More flexible casting processes:

In aluminium die casting, it is also necessary to be able to respond more flexibly to customer requests. Central recipe management and automatic changing of cooling parameters during mould changes are crucial here to be able to guarantee all customers consistent component quality, even if there are multiple mould changes.

Intelligent cooling media cabinets:

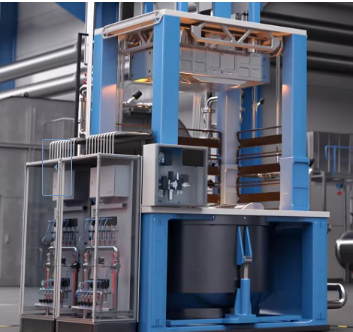

The intelligent cooling media cabinets from Bürkert make a significant contribution to designing and implementing efficient cooling concepts in the foundry. On the PC, the individual cooling parameters can be set, continuously monitored and documented so that any errors can be immediately identified and corrected. At the same time, the cooling is always precisely matched to the respective component so that cycle times can be shortened.

Precise gas control for degassing units:

Bubbles contained in molten aluminium become undesirable cavities after solidification, which have a detrimental effect on the mechanical properties of the cast parts. To order to avoid this formation of bubbles and maintain a constant melt quality, degassing devices are used in practice in which a rotor generates very fine purge gas bubbles – preferably argon or nitrogen – and mixes them with the melt. Bürkert mass flow controllers precisely control the purging gases and thus make an important contribution to consistently high melt quality.

Efficiently designing customised fluid handling for the die casting industry:

Burkert also analyses processes because as fluidics experts, we develop solutions for your aluminium die casting applications – from customised components to individually tailored systems. You will find a selection here – discover more with a non-binding consultation.

Low-Pressure Die Casting:

The Requirement:

Efficient cooling for low-pressure casting.

The Burkert Solution:

Burkert offers compact cooling solutions in the control cabinet either as air cooling, water cooling, or combined air/water cooling.

Degassing:

The Requirement:

Efficient gas control.

The Burkert Solution:

Burkerts MFCs efficiently control the process gases in your degassing system.

Bürkert Systemhaus – always open for fluidics technology requirements in the aluminium die casting industry:

The development of reliable fluid handling solutions in the die casting industry is complex and time-consuming. Use the know-how of our fluidics specialists to operate more efficiently. We listen, analyse and develop future-oriented products and customer-specific application solutions until they are ready for series production. You and your projects are always welcome in the Systemhaus – on site, by telephone or virtually.

Manufacturing Ideas:

Manufacturing Ideas:

Experienced consultants, qualified industry specialists, and dedicated engineers work directly with you to develop solutions for your project-specific requirements in aluminum die casting. Thanks to Burkert’s network of five Systemhaus locations in Germany, China, and the US, you can rely on flexible and efficient project management – from the initial idea to implementing the solution in the die-casting machine or degassing unit.

Measurably Safe, Measurably Efficient:

View all Burkert Fluid Control System parts

Manufacturing Ideas:

Manufacturing Ideas: