The inductive ring sensors enable precise and reliable detection of small metal parts in feed hoses. The correction factor 1 ensures reliable detection of all metal objects from a size of 2 mm. Thanks to the robust soft binder, the sensor can be fixed securely even in challenging environments with vibrations or compressed air.

![]() Wenglor Inductive Sensor Flyer

Wenglor Inductive Sensor Flyer

Main Features:

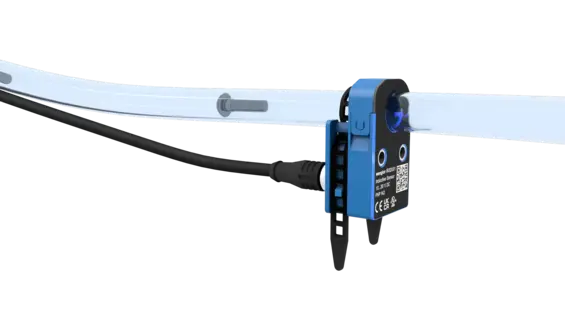

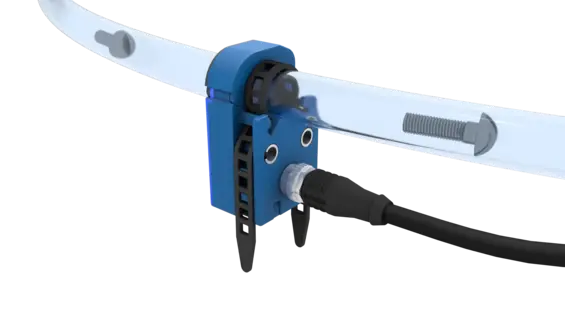

- Separable housing

- Cable outlet in hose direction

- Flexible soft binder on the sensor

- Switching status indicator visible all the way around

Separable Housing:

- Quick and flexible installation and removal of the sensor on the hose

- Minimize machine downtime when replacing hoses and during repairs

- Detection of metal objects anywhere in the active field

- Coil is divided into two parts

Cable Outlet in Hose Direction:

- Cable is routed parallel to the hose

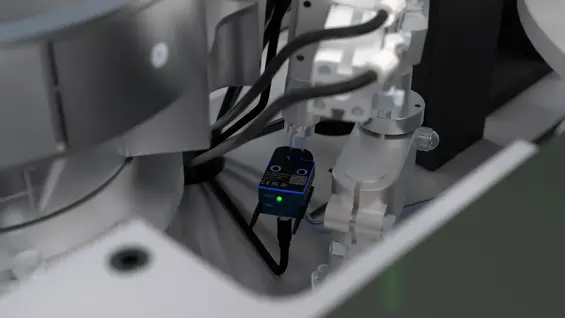

- Sensor is particularly suitable for confined spaces

- No obstruction of the system design due to the cable routing of the sensor

- No kinks in the cable

Flexible Soft Binder on the Sensor:

- Easy and secure mounting on different hose sizes

- Stable fixing in vibrating environments, such as vibrating spiral conveyors or compressed air conveyors

- Can be used multiple times, as non-destructive opening is possible, additional loss protection

- No tapering of the hose possible

Switching Status Indicator Visible All the Way Around:

- Completely visible LED display

- Switching operation can be detected regardless of the installation position

- Color display:

- Blue: power supply indicator

- Yellow: switching operation

- Red: error

Other Advantages of Inductive Ring Sensors:

Plug and Play: Inductive ring sensors can be easily installed via Plug & Play and quickly put into operation without prior adjustment.

Easy-to-Use Controls: Thanks to the potentiometer and IO-Link interface, inductive ring sensors offer flexible operating options for reliably reading out and processing parameters and process data.

Correction Factor 1: Thanks to the correction factor 1, inductive ring sensors reliably detect objects made of different non-ferrous metals from a size of 2 mm.

Functional Principle Static: Static ring sensors detect rapidly moving objects or objects that remain constantly inside the ring, e.g. for bottleneck monitoring.

Functional Principle Dynamic: Dynamic ring sensors are used to detect the smallest, fast moving objects, such as ejection control of rivets.

Applications with Limited Space Availability: Thanks to the compact format and integrated weproTec technology, several sensors can be installed directly next to each other in the tightest of spaces without interfering with each other.

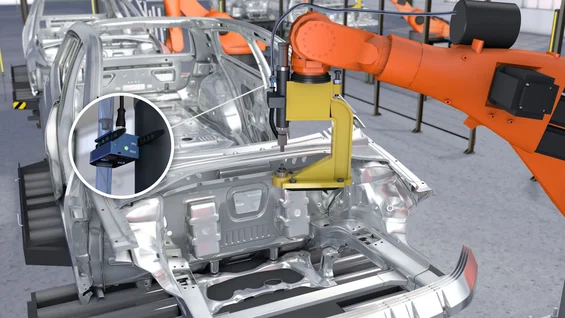

In assembly and feeding technology, fasteners such as screws, nuts and rivets are automatically conveyed, sorted and separated by feeding systems. These are supplied to the screw system via feed hoses by compressed air. Inductive ring sensors mounted on the hose detect metal parts as small as 2 mm at high speed. The separable housing enables easy assembly and disassembly. The presence of the parts is visualized by all-round lighting.