Where complex shapes are measured, surfaces and colors of objects vary, maximum precision in the micrometer range and temperature-stable measured values are required, the triangulation laser distance sensors from the P3 series unleash their unrivaled performance – thanks, among other things, to the unique TripleA technology. CMOS sensors can be used for various applications at distances of up to 1,000 mm. The P3 sensors detect even small differences in height with reproducibility of up to 0.8 µm using a highly accurate triangulation process.

Strong Performance:

Precision:

Precision:

- Excellent optical imaging thanks to specially curved glass lenses

- Precise measurement results with a linearity deviation of just 0.08%

- Detection of the small objects with reproducibility of up to 0.8 μm

- Detection of very flat objects directly in front of a background

- Optimal measurement of objects at extreme angles

- Digital access to the calibration report stored in the sensorP3 laser distance sensors material independence

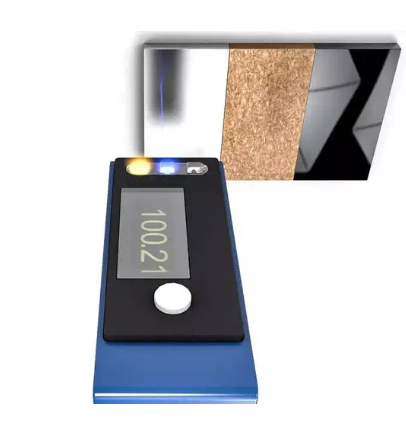

Material Independence:

Material Independence:

- Automatic adjustment of the CMOS chip exposure time

- Reliable detection on different object colors and brightness

- Stable measured values independent of the object’s degree of reflection

- Reliable measurements on dark, light or low reflecting objects regardless of the degree of reflection

- Highly accurate switching to different objects

Temperature Stability:

Temperature Stability:

- High temperature stability due to low temperature drift of up to 2.5 µm/K

- Very fast availability of stable measured values in < 5 minutes after system start-up thanks to built-in temperature sensors

- High-quality glass lenses and temperature-stable aluminum housing

- Suitable for use in a temperature range from –30 to +60 °C

Innovative Functions for a Wide Range of Applications

Dynamic Jump Detection:

Dynamic Jump Detection:

Jump detection is one function of the P3 laser distance sensors. The changes in the measured value, i.e. the jumps, are evaluated rather than the absolute distances. Jump detection can be used as an edge counting method, e.g. when counting newspapers on a conveyor.

- Stable detection of flat objects on uneven surfaces

- Reliable spill counting thanks to detection of measured value jumps

- Insensitive to misalignment due to slight change in distance

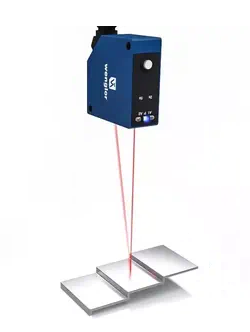

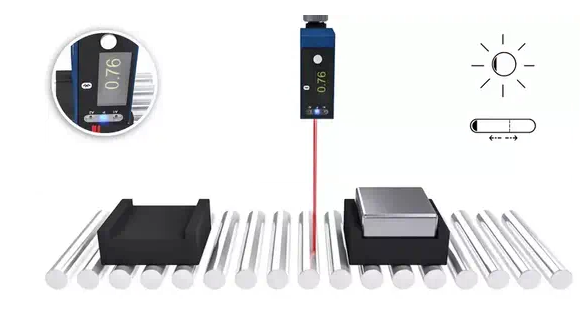

Thickness and Differential Measurement without Analysis Module:

Laser triangulation sensors are arranged opposite each other for thickness measurement. The sensors use the triangulation method to detect the distance to the object and calculate the thickness of the measured object from both values.

Laser triangulation sensors are arranged opposite each other for thickness measurement. The sensors use the triangulation method to detect the distance to the object and calculate the thickness of the measured object from both values.

- Measurement results can be read directly on the display without an analysis module and programming in the control unit

- Easy cabling and automatic configuration with optional connection cable

- Contactless product thickness measurement

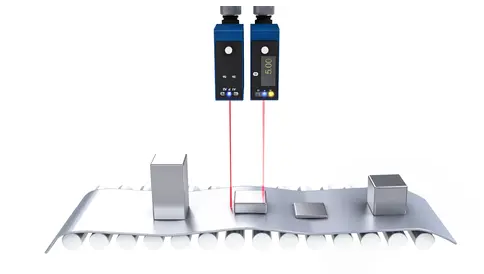

For differential measurement, laser distance sensors are arranged next to each other. A sensor measures the distance to a background, for example a conveyor belt, and another sensor measures to the object. The difference between the two measured values is calculated and output directly by the main sensor.

For differential measurement, laser distance sensors are arranged next to each other. A sensor measures the distance to a background, for example a conveyor belt, and another sensor measures to the object. The difference between the two measured values is calculated and output directly by the main sensor.

- Precise height measurement even on uneven backgrounds

- Contactless product height measurement

- Measurement result can be read directly on the display

Intensity Evaluation for Part Control:

The laser distance sensors evaluate not only the measured distance, but also the light intensity received from the object. This is how contrast differences are detected.

The laser distance sensors evaluate not only the measured distance, but also the light intensity received from the object. This is how contrast differences are detected.

- Easy part monitoring for height and color

- Error monitoring for the highest product quality

- Detection of transparent objects with constant background

Applications:

- Presence Check

- Thickness Measurement

- Diameter Control

- Edge Counting

- Positioning

- Robot Positioning

- Stack Height Monitoring

- Past Measurement

- Monitoring of Two-Layer Materials