From water extraction and treatment to water distribution and wastewater treatment, Pfannenberg ensures the reliable operation of water-conducting systems worldwide.

Application Areas:

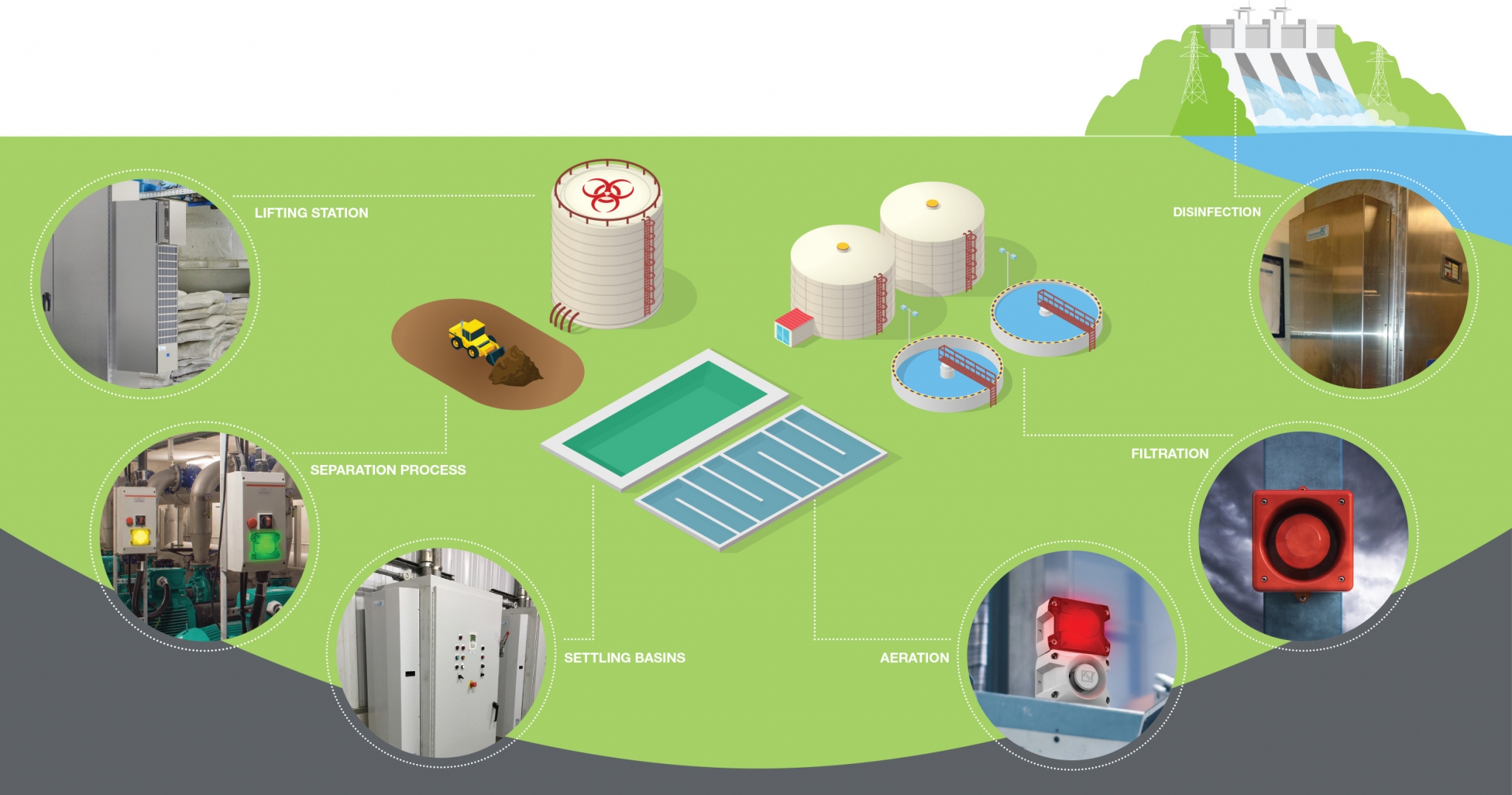

Lift Stations: Lift stations are critical to the overall infrastructure of wastewater treatment centers. Our cooling systems maintain optimal operating conditions for variable frequency drives (VFDs) in pumps, therefore our DTS units provide a tight enclosure seal preventing enclosure contamination and oxidation of components. Pfannenberg’s signaling and gas alarms ensure employee and process safety.

Lift Stations: Lift stations are critical to the overall infrastructure of wastewater treatment centers. Our cooling systems maintain optimal operating conditions for variable frequency drives (VFDs) in pumps, therefore our DTS units provide a tight enclosure seal preventing enclosure contamination and oxidation of components. Pfannenberg’s signaling and gas alarms ensure employee and process safety.

Separation Process: In the screening, pumping, and grit removal stage, Pfannenberg provides adequate signaling solutions to secure alarm coverage, avoid signaling confusion, and ensure gas detection. Pfannenberg also provides critical thermal management systems to cool control equipment and VFDs in pumps. Additional drive or control systems on conveyors, dewatering presses, centrifuges, and scrubbers are similarly protected.

Separation Process: In the screening, pumping, and grit removal stage, Pfannenberg provides adequate signaling solutions to secure alarm coverage, avoid signaling confusion, and ensure gas detection. Pfannenberg also provides critical thermal management systems to cool control equipment and VFDs in pumps. Additional drive or control systems on conveyors, dewatering presses, centrifuges, and scrubbers are similarly protected.

Settling Basins: Settling, or Clarifying Basins, with massive pumps to move sludge out, and send floating or other debris to digesters, require numerous electronics for moving the liquid to the appropriate equipment. Pfannenberg’s cooling equipment ensures longevity for pumping and control systems, and evacuation alarms for fires or potential leaks from chemicals are added to remove phosphorus and odor control.

Settling Basins: Settling, or Clarifying Basins, with massive pumps to move sludge out, and send floating or other debris to digesters, require numerous electronics for moving the liquid to the appropriate equipment. Pfannenberg’s cooling equipment ensures longevity for pumping and control systems, and evacuation alarms for fires or potential leaks from chemicals are added to remove phosphorus and odor control.

Aeration/Sludge Handling: Pfannenberg provides critical enclosure cooling for aeration blowers, powered by VFDs- the largest single consumer of energy in wastewater plants. For safety in sludge handling, Pfannenberg offers SIL-compliant signaling devices with hazardous area certifications.

Aeration/Sludge Handling: Pfannenberg provides critical enclosure cooling for aeration blowers, powered by VFDs- the largest single consumer of energy in wastewater plants. For safety in sludge handling, Pfannenberg offers SIL-compliant signaling devices with hazardous area certifications.

Filtration: In the filtration area, disc filters and pumps require significant cooling, most often with DTS Cooling Units which utilize closed loop cooling to ensure the best temperature control in tough industrial or outdoor applications.

Filtration: In the filtration area, disc filters and pumps require significant cooling, most often with DTS Cooling Units which utilize closed loop cooling to ensure the best temperature control in tough industrial or outdoor applications.

Disinfection: Where disinfection includes chlorine, Pfannenberg’s SIL-compliant devices with hazardous explosive area certifications are available. PWS Water Air/Water Stainless steel NEMA type 4X units help prevent corrosion and visible oxidation in disinfection areas.

Disinfection: Where disinfection includes chlorine, Pfannenberg’s SIL-compliant devices with hazardous explosive area certifications are available. PWS Water Air/Water Stainless steel NEMA type 4X units help prevent corrosion and visible oxidation in disinfection areas.

Products for Wastewater Solutions Include:

Ideal for water & wastewater treatment automation where:

- Ambient conditions are at their worst

- Machines are cooled by existing tempered water

Ideal for these areas:

- Grit Removal

- Screening and Pumping

Ideal for water & wastewater treatment automation where:

- High temperatures up to 140° F (60° C)

- Wash down requirements

- Component-damaging chemicals

Ideal for these areas:

- Lift stations

- Disinfection

- Odor Control

Ideal for water & wastewater treatment automation where:

- Temperature controlled environment

- Wash down requirement

- Protection against corrosion and contamination

- Energy conscious

Ideal for these areas:

- Sludge handling

Stack Lights, Signaling, and Arms

Stack Lights, Signaling, and Arms

Ideal for water & wastewater treatment automation where:

- Machine alarming, indications, or warning required

- H2S, Chlorine, or odor-reducing chemical Leaks/Prevention and Detection required

Ideal for these areas:

- Aeration

- Sludge Handling

- Settling Basins and Clarifiers

- Lift Stations

- Disinfection

Ideal for water & wastewater treatment automation where:

- The air temperature does not exceed 95F

- Areas exposed to outdoors or heavy spray

Ideal for these areas:

- Lift Stations

Lift Stations: Lift stations are critical to the overall infrastructure of wastewater treatment centers. Our cooling systems maintain optimal operating conditions for variable frequency drives (VFDs) in pumps, therefore our DTS units provide a tight enclosure seal preventing enclosure contamination and oxidation of components. Pfannenberg’s signaling and gas alarms ensure employee and process safety.

Lift Stations: Lift stations are critical to the overall infrastructure of wastewater treatment centers. Our cooling systems maintain optimal operating conditions for variable frequency drives (VFDs) in pumps, therefore our DTS units provide a tight enclosure seal preventing enclosure contamination and oxidation of components. Pfannenberg’s signaling and gas alarms ensure employee and process safety. Separation Process: In the screening, pumping, and grit removal stage, Pfannenberg provides adequate signaling solutions to secure alarm coverage, avoid signaling confusion, and ensure gas detection. Pfannenberg also provides critical thermal management systems to cool control equipment and VFDs in pumps. Additional drive or control systems on conveyors, dewatering presses, centrifuges, and scrubbers are similarly protected.

Separation Process: In the screening, pumping, and grit removal stage, Pfannenberg provides adequate signaling solutions to secure alarm coverage, avoid signaling confusion, and ensure gas detection. Pfannenberg also provides critical thermal management systems to cool control equipment and VFDs in pumps. Additional drive or control systems on conveyors, dewatering presses, centrifuges, and scrubbers are similarly protected. Settling Basins: Settling, or Clarifying Basins, with massive pumps to move sludge out, and send floating or other debris to digesters, require numerous electronics for moving the liquid to the appropriate equipment. Pfannenberg’s cooling equipment ensures longevity for pumping and control systems, and evacuation alarms for fires or potential leaks from chemicals are added to remove phosphorus and odor control.

Settling Basins: Settling, or Clarifying Basins, with massive pumps to move sludge out, and send floating or other debris to digesters, require numerous electronics for moving the liquid to the appropriate equipment. Pfannenberg’s cooling equipment ensures longevity for pumping and control systems, and evacuation alarms for fires or potential leaks from chemicals are added to remove phosphorus and odor control. Aeration/Sludge Handling: Pfannenberg provides critical enclosure cooling for aeration blowers, powered by VFDs- the largest single consumer of energy in wastewater plants. For safety in sludge handling, Pfannenberg offers SIL-compliant signaling devices with hazardous area certifications.

Aeration/Sludge Handling: Pfannenberg provides critical enclosure cooling for aeration blowers, powered by VFDs- the largest single consumer of energy in wastewater plants. For safety in sludge handling, Pfannenberg offers SIL-compliant signaling devices with hazardous area certifications. Filtration: In the filtration area, disc filters and pumps require significant cooling, most often with DTS Cooling Units which utilize closed loop cooling to ensure the best temperature control in tough industrial or outdoor applications.

Filtration: In the filtration area, disc filters and pumps require significant cooling, most often with DTS Cooling Units which utilize closed loop cooling to ensure the best temperature control in tough industrial or outdoor applications. Disinfection: Where disinfection includes chlorine, Pfannenberg’s SIL-compliant devices with hazardous explosive area certifications are available. PWS Water Air/Water Stainless steel NEMA type 4X units help prevent corrosion and visible oxidation in disinfection areas.

Disinfection: Where disinfection includes chlorine, Pfannenberg’s SIL-compliant devices with hazardous explosive area certifications are available. PWS Water Air/Water Stainless steel NEMA type 4X units help prevent corrosion and visible oxidation in disinfection areas. PWS Air/Water Heat Exchangers

PWS Air/Water Heat Exchangers DTS Cooling Units

DTS Cooling Units PKS Air/Air Heat Exchangers

PKS Air/Air Heat Exchangers Filterfan® with Rainhood

Filterfan® with Rainhood