The PRD series cylindrical inductive proximity sensors are available in standard and IO-Link communication models. The sensors feature long sensing distances and excellent noise immunity. Available in various sizes and sensing distances, the high performance cylindrical inductive sensors can be used in diverse applications requiring non-contact detection of metallic objects. The sensors also feature strain relief cables for improved flexural strength and durability.

Main Features:

- DC 4-wire M12, M18, M30 size IO-Link communication models have been added to the lineup

- Operation indicator (red LED)

- Communication indicator for IO-Link model (orange, green LED)

- IP67 protection structure (IEC standard)

- Strain relief cables: improved flexural strength of cable connecting component (except M8 models)

- PTFE coating prevents malfunctions caused by welding spatter (spatter-resistant model)

Available in various cable types including cable, cable connector, and connector types.

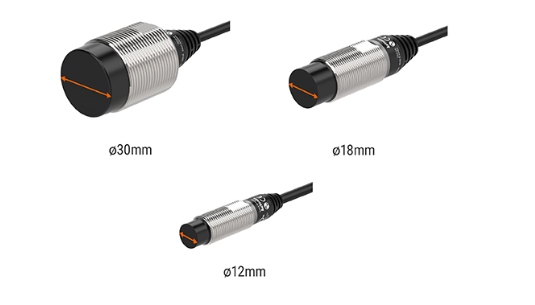

Available in various M12, M18, and M30 size models.

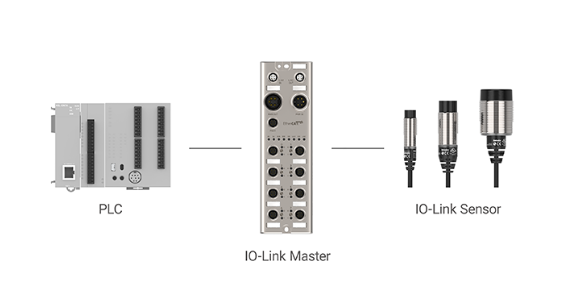

IO-Link allows bi-directional exchange of data between sensor and control level.

With IO-Link communication, sensors can be monitored in real-time with specific IDs applied for instant and quick recovery.

Operation indicator and stability indicator allows users to quickly identify operation stats from various angles.

Advantages of IO-Link Sensors:

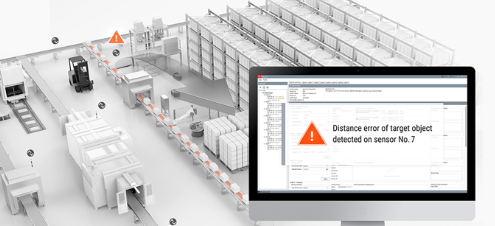

Predictive Maintenance: Sensors data can be transmitted before abnormal symptoms appear to prevent malfunction due to wear or dust of mechanical parts in advance.

Predictive Maintenance: Sensors data can be transmitted before abnormal symptoms appear to prevent malfunction due to wear or dust of mechanical parts in advance.

Reduce Downtime:

Reduce Downtime:

Data of sensor malfunction and causes can be transmitted in real-time, making it easy to check the location and cause of the sensor for reducing downtime.

Easy Maintenance:

Easy Maintenance:

As individual sensor IDs can be checked collectively. It is possible to reduce manpower waste in checking sensor errors.