Continuous monitoring of Ethylene and Carbon dioxide in ripening rooms

Fruits and vegetables are shipped long distances from one country to another often before they are ripe so they can endure the voyage and remain viable. Upon arrival, they need to be ripened so they can be sold and consumed. To speed up the process, ethylene is introduced at concentrations between 10 and 1,000 ppm depending on the type of produce and environmental conditions in the air-tight ripening room.

Ethylene is not toxic at these concentrations, but it is a very reactive and flammable gas, making the potential for an explosion a safety concern. There is the potential for ethylene to leak from the high pressured gas cylinders, the ethylene generator or from one room into another, especially if the method of delivery is through a network of pipes. This could cause premature ripening or result in damage to the other types of produce in adjacent rooms. Monitoring the concentration levels of the ethylene gas in each room will help ensure the correct amount is always being delivered.

As fruit ripens, it releases carbon dioxide. This decreases the oxygen level in the room and delays the effects of the ethylene. CO2 levels in excess of 1% (10,000 ppm) will slow the ripening process and can cause quality and production problems. When CO2 levels build up, the ripening room should be vented, which could be as simple as opening the door, or turning on a ventilation system.

KEY CONSIDERATIONS

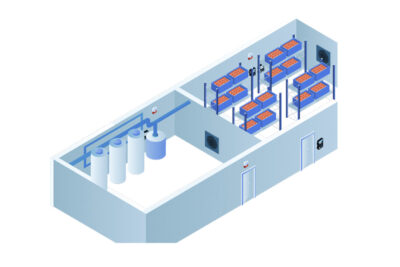

- Two ethylene gas detectors one inside the ripening room mounted 6-7 ft / 72-84 in for plant health and another mounted in the ethylene storage or generator room where potential leaks could occur

- One CO2 gas detector mounted inside the ripening room mounted at plant height for plant health

- Gas detection system controls the flow of ethylene and triggers the ventilation system

- Audible / visual devices should be mounted high up on the walls or columns

TARGET GASES

- Ethylene (C2H4)

- Carbon Dioxide (CO2)