In the realm of industrial heating, Tempco cartridge heaters stand out for their efficiency, versatility, and innovative design. These heaters are essential in various applications, providing precise temperature control for processes that require direct heat.

What Are Cartridge Heaters?

Cartridge heaters are cylindrical heating elements designed to provide direct heat to specific surfaces or materials. Tempco, a prominent manufacturer in this field, produces high-quality cartridge heaters that cater to diverse industrial needs. These heaters are typically inserted into a bore or hole in a metal block or other materials to transfer heat directly and efficiently.

Key Features of Tempco Cartridge Heaters

Construction: Tempco cartridge heaters are made from high-quality stainless steel or Inconel, providing excellent resistance to corrosion and oxidation. This durability ensures longevity, even in demanding environments.

Variety of Wattages and Sizes: Available in a range of wattages and diameters, these heaters can be customized to meet specific application requirements. This flexibility allows for precise temperature control based on the application needs.

Thermal Response: Tempco cartridge heaters boast rapid thermal response times, allowing for quick heating and cooling. This feature is crucial in applications where temperature consistency is vital.

Voltage Options: They come in various voltage ratings, making them suitable for different electrical systems. This adaptability enhances their usability across various industries.

Custom Design Capabilities: Tempco offers customization options for their cartridge heaters, allowing clients to tailor heaters to specific dimensions, watt densities, and other requirements.

Benefits of Tempco Cartridge Heaters

Efficiency: The design of cartridge heaters enables efficient heat transfer, which minimizes energy consumption and reduces operating costs.

Versatility: Tempco cartridge heaters are used in numerous applications, from plastic molding and packaging machinery to food processing and medical equipment.

Easy Installation: These heaters are relatively simple to install, often requiring minimal tools and expertise, which can save time and labor costs during setup.

Reliability: Built to withstand harsh conditions, Tempco cartridge heaters have a reputation for reliability, which is critical in preventing downtime in industrial processes.

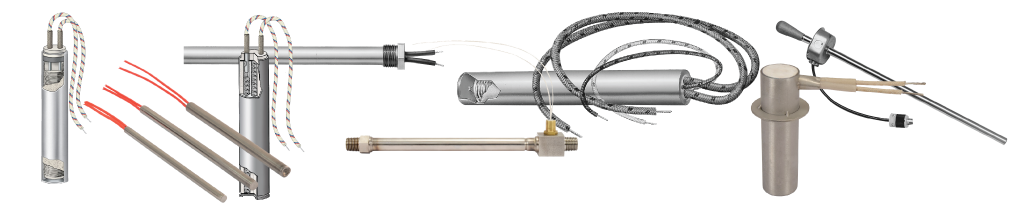

Types of Cartridge Heaters:

Hi-Density Cartridge Heaters: Hi-density cartridge heaters are designed for high-wattage applications where efficient heat transfer is crucial. With a higher watt density, these heaters can deliver more heat in a compact space.

Hi-Density Miniature Cartridge Heaters: Similar to Hi-density cartridge heaters but designed for smaller applications, these miniature heaters are ideal when space is at a premium.

Low-Density Cartridge Heaters: Low-density cartridge heaters operate at lower watt densities, making them suitable for applications where high temperatures are not necessary.

Immersion Cartridge Heaters: Immersion cartridge heaters are designed to be submerged in liquids or materials, providing direct heating. They feature a sealed construction to withstand harsh environments.

In-Line Forced Air Heaters: These heaters are designed to provide consistent heat in an air stream, using forced air to enhance heating efficiency. They are ideal for applications that require rapid heating of air.

Pennybottom Cartridge Heaters: Pennybottom cartridge heaters are designed specifically for applications with limited space, featuring a unique design that allows for efficient heat distribution.

Underwater Pelletizer Die Cartridge Heaters: Designed for underwater pelletizing systems, these heaters ensure consistent temperature control for die plates, crucial for producing high-quality pellets.

Bolt Cartridge Heaters: Bolt cartridge heaters feature a unique design that allows them to be mounted securely, providing stable heating in various applications. Their bolt design facilitates easy installation and replacement.