They are constructed using a 6063 aluminum finned body and a welded flange. The lightweight outer finned structure in contact with the heated media provides a low watt density surface in shorter immersion lengths for heating sensitive organic fluids that are susceptible to coking and carbonization.

Design Features

- 3″- 150 lb rated 7 1/2″ OD Aluminum Flange and Gasket

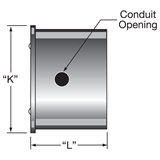

- 2-7/8″ OD Finned body designed for 3″ Schedule 40 pipe

- 2″OD × 5″ long un-finned area under flange for fluid inlet

- 1/4-20 threaded studs for secure connections to power supply

- Flange mates to standard 3″ CHF Circulation Heater pipe body

Optional Features

- Single- or three-phase designs from 120V to 600V maximum

- 3″ — 300 lb & 600 lb rated Aluminum mounting flanges

- Optional internal overtemperature type K or J thermocouple sensor in heated zone. 24″ pigtail leads standard in housing. (700°F maximum controller setting)

- Alternate size ASA style Flanges – 3-1/2″ & 4″ in 150 lb ratings

- Round, rectangular/square non-pressure rated Aluminum mounting flanges.

- 3″ or 4″ size cast aluminum screw plug mounting in place of flange

- Finned area watt densities 4 -16 for oil/organic fluids

- External power wiring options including armored cable, braided or plain lead wire

Eagle Sensors & Controls, Division of Excel Automation LLC, is an authorized Tempco distributor. Contact us for sales & technical support for Tempco heaters, Tempco sensors, Tempco temperature controllers, Tempco process heating systems & all other Tempco products.