Carefully researched manufacturing methods and quality materials have made Tempco tubular heaters stand apart from other heating elements claiming similar performance.

A computer-designed helical coil of 80% Nickel 20% Chromium alloy resistance wire is fusion welded to the nickel-coated steel terminal cold pin. This coil assembly is precisely stretched and centered in the element metal sheath, which is then filled with Grade “A” Magnesium Oxide powder (MgO). The filled tube is then compacted by a roll reduction mill into a solid mass, permanently stabilizing the coil in the center of the tube while providing excellent heat transfer and dielectric strength between the coil and the sheath.

Eagle Sensors & Controls, Division of Excel Automation LLC, is an authorized Tempco distributor. Contact us for sales & technical support for Tempco heaters, Tempco sensors, Tempco temperature controllers, Tempco process heating systems & all other Tempco products.

- Sheath Materials

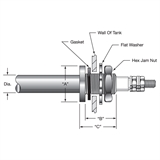

- Mounting Options

- Surface Treatments

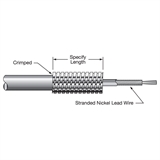

- Electrical Terminations

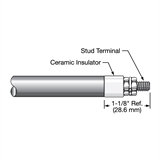

- Termination Options

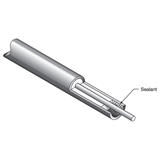

- Moisture Seals