Hermetic Tightness Thanks to Stainless Steel 316L Housing

- IP68/IP69K high-pressure washdown protection

- High-quality housing and plug made of stainless steel 316L (1.4404)

- Hygienic installation thanks to bayonet catch

- Resistant to cleaning agents with ECOLAB® approval

- FDA compliant for use in the food industry

- Temperature range from –30 to +60 °C

Strong Performance and High Flexibility

- Working range in reflex mode up to 1,100 mm

- Working range in through-beam mode up to 2,000 mm

- Variants with switching and analog output available

- Gap-free installation option for the highest hygiene requirements

- Standard M12 plug for maximum flexibility

Excellent Positioning:

Whether cleaning agents, vapors from acids or direct contact with chemical media – the stainless steel ultrasonic sensors are completely resistant due to their hermetically sealed stainless steel housing.

Diverse Usage Options:

- Presence Check

- Positioning

- Fill Level Monitoring

- Through-beam sensor

Applications

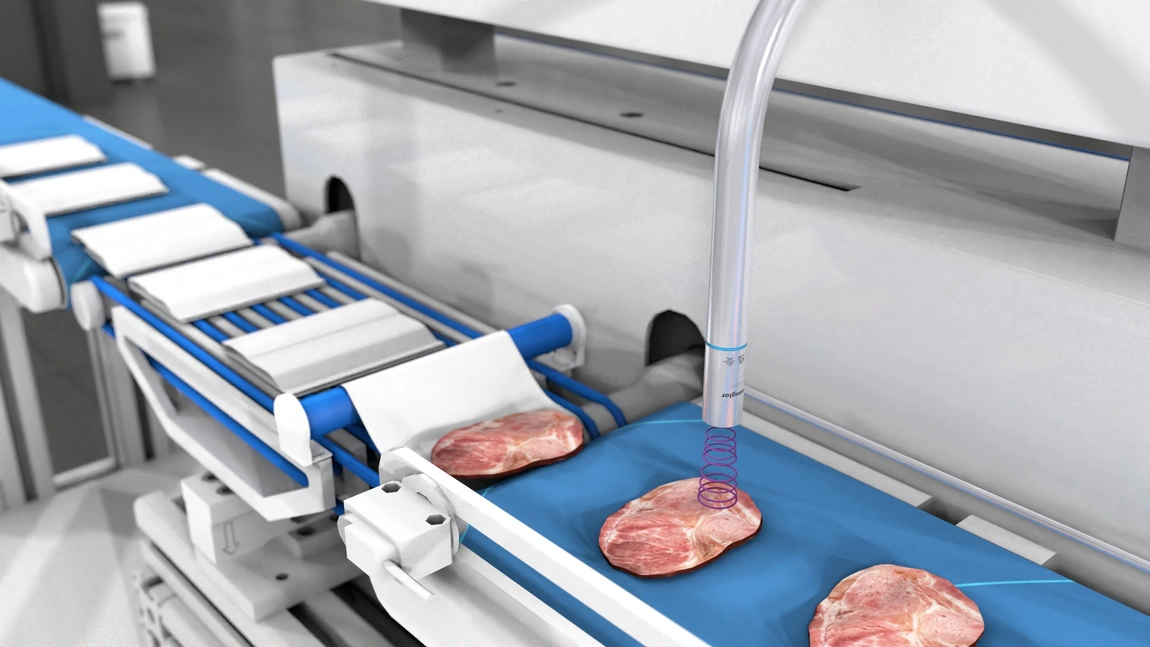

Detection of Food on Conveyor Belts with Hygienic Ultrasonic Distance Sensor: When packaging foods such as ham, cheese, fish or bacon, the objects portioned into slices are transported on conveyor belts and first wrapped in paper. To ensure that the paper is placed at the right moment, an ultrasonic sensor must first reliably detect the incoming food despite different colors, shapes and surfaces. The sensor in the hygienic stainless steel housing is mounted above the conveyor line. Thanks to IP69K protection, high-pressure cleaning (up to 100 bar) at a water temperature of 80 °C and with aggressive cleaning agents is possible.

Fill-Level Measurement of Spices in Frozen Pizza Production via Ultrasonic Sensor: Frozen pizzas are produced and the toppings added in highly automated production facilities. Spices such as oregano are sprinkled on top of the pizzas after the toppings have been added. The spice mixture is located in an open container directly above the conveyor belt. An ultrasonic distance sensor in a hygienic stainless steel housing monitors the container to detect the exact fill level at all times so the container can be refilled in good time. The level can be continuously monitored thanks to the analog output.