It is crucial for both the electrical and mechanical components used in the fuel cell to work safely and reliably in order for it to be used in mobile applications. In order to avoid downtime and minimise maintenance costs, it must be guaranteed that they can function under harsh operating conditions for a long period.

Bürkert products and solutions meet very high safety requirements thanks to the necessary approvals and durability. Long maintenance intervals and energy-saving solutions contribute to the efficient utilisation of your fuel cell. Our components are suitable for use with hydrogen and guarantee reliable operation.

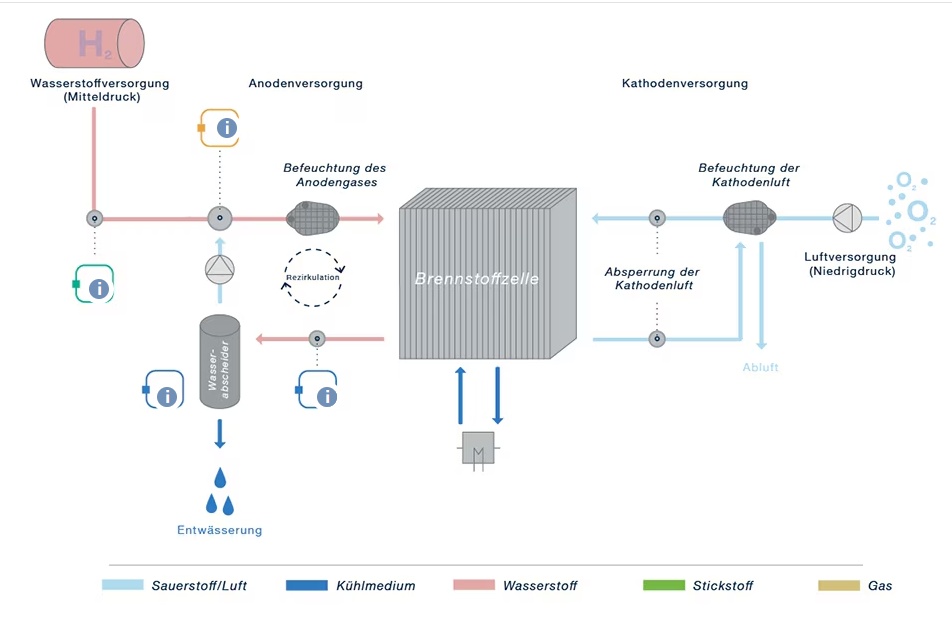

Safe Hydrogen Shut-Off:

Reliable shut-off of the hydrogen ensures trouble-free operation and extends the maintenance intervals of the mobile fuel cell. Due to the special properties of hydrogen, our valves also ensure safe shut-off, which reliably prevents potential risks and optimises safety standards.

Stack Pressure Control:

The high-resolution, highly dynamic proportional controller ensures reliable pressure control, either in high back pressure conditions (recirculation via passive pump) or low back pressure conditions (recirculation via active pump).

Flushing and Draining the Recirculation Circuit:

Efficiently controlling hydrogen in mobile fuel cells not only enables an efficient fuel supply, but also plays a decisive role in flushing and draining the recirculation circuit. This precise control not only helps to increase the performance and extend the service life of the fuel cell by protecting against undesirable chemical reactions and wear, but also ensures long-term operational reliability and protects against unexpected failures.