Below is typical diffusion pump installation. They are normally mounted 3-6” off the floor and are used primarily in heat treating & vacuum deposition systems. These simple vacuum systems have no moving parts and rely on a simple heater attached to the bottom of the boiler plate to work.

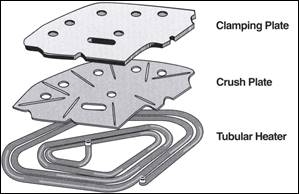

Originally, these pumps used a clumsy inefficient 3 piece design pictured above. With very little clearance under the pump, an acrobatic maintenance worker must balance all three parts together to install. Worse, these elements would not last long and relied on inefficient radiant heat transfer to convey heat into the pump.

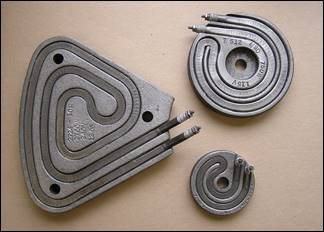

Then along comes Dalton. William Dalton’s co-founder Walter Churchill and a team of Dalton employees came up with an ingenious solution of combining the heating element into a casting pictured below.

The idea took shape and eventually became the patented Diff-Therm® heater. This concept substantially improved the ease of installation. Moreover, the team stumbled on the life extending benefits of compacted insulation. Today, Dalton Electric’s Diff-Therm® is the standard barer for diffusion pump heating. Supplying many of OEM’s as well as a host of global vacuum pump distributors.