This week Dalton concludes their 3-part series on testing with a critical look at resistance. As a reminder, Dalton runs every heater through an 8-point Testing and Inspection check list that include the three electrical tests below:

- Megohm – tests insulation media

- Hipot – can the insulation withstand spike voltage

- Resistance – can resistance coil reach desired power (set temp.)

From an operational point, resistance is the most important value since it determines whether a heater will work or not in each application.

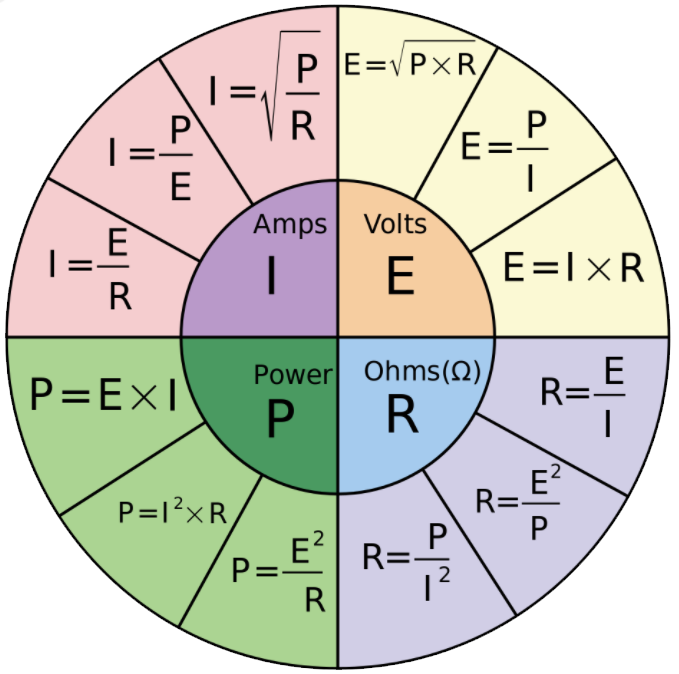

Fundamentally, resistance is a measure of the opposition to current flow in an electrical circuit – ohms, symbolized by the Greek letter omega (Ω). Georg Simon Ohm (1784-1854), a German mathematician uncovered the mathematical relationship between resistance, voltage, and current in a groundbreaking scientific report published in 1827. The chart below shows the various mathematical relationships to Ohm’s Law.

Resistance measurements are normally taken to indicate the condition of a component or a circuit. Resistance is inversely proportional to power (see lower left quadrant of chart above).

Simply put:

- Higher resistance – Less power.

- Lower resistance – More power.

Dalton also knows that heater resistance increases due to 3 basic conditions:

- A onetime increase on First Heat Up (initial oxidation of the coil)

- Resistance increases as resistance coil Temperature goes up

- Resistance increases as resistance coil ages (ongoing oxidation)

Given Dalton’s understanding of the above conditions and 50+ year experience making split heaters, we skew our resistance range to anticipate these conditions (+4.5% / -15%). This simple technique generates more hours of heater life. Whereas, most conventional heater companies resistance value tolerance is +/- 10%.